Our Capabilities

Bureau

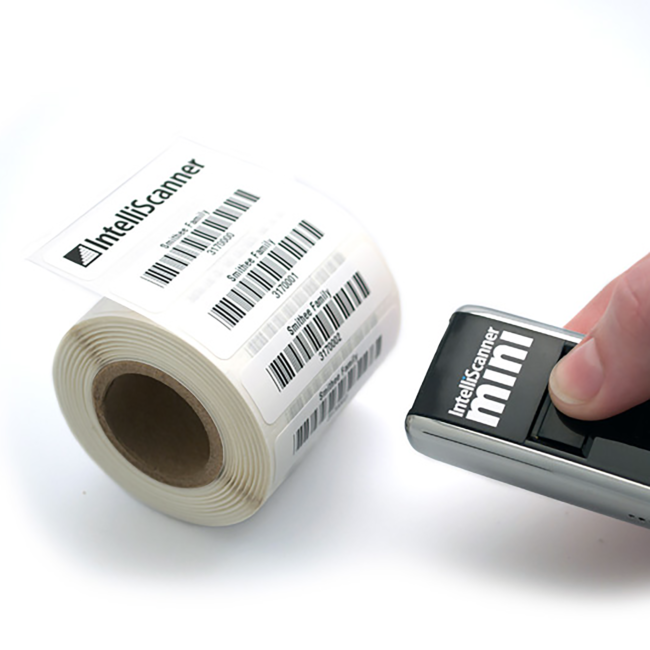

We have a dedicated bureau department for producing labels with barcodes, variable information and encoding RFID inlays

We can produce a wide variety of barcode types including code 39, code 128, QR codes, data matrix and many more. Our team have extensive experience in producing barcode labels including the most complex designs requiring check digits, randomized numbering and links to Microsoft Excel Databases.

Our print quality ranges from 200 – 600 d.p.i to ensure we can print the highest quality for the required design. As well as printing we can also encode RFID inlays.

We have the option to print via thermal transfer or onto direct thermal materials.

We stock a range of thermal transfer ribbons including standard wax, wax / resin, full resin and specialist chemical resistant ribbon. This allows us to print on a wide variety of substrates including paper, polyester, vinyl, polypropylene, polyimide and many more. Again, our team have the extensive experience in selecting the correct combination of ribbon and substrate to ensure the durability and quality of the finished label are suitable for the required application.

- Multiple Barcode Types

- Sequential Numbering

- RFID Encoding

- Low – Medium Quantities

- Print onto Various Substrates

- Rolls or Sheets

- No Printing Plate Required

Get in touch today

“Thank you to Derry and everyone else at The Label Centre for your efficient and high-quality service. I highly recommend!"

Simon, Industrial Labels & Nameplates Ltd.

“Professionalism, Quality, Responsiveness, Value"

Mick Detheridge, MD Mobile Caravan Services.

"Labels made to order Good prices fast service what more would you want would recommend"

Phil Wright, Google Review.